i-500

Commercial-grade Portable Vision-Screener

Titmus asked BH to design a unique, ergonomically superior vision screener that vastly improved usability over its existing device which severely hampered the smooth testing of patients due to poor ergonomics. The project had to solve difficult features such as provide a simple means to point at test-slide images without disrupting the workflow, and portable with a form factor and kinematics that enhanced the fit of the subject's face to the device. Titmus also desired the new device be available to launch in a 12 month lead time.

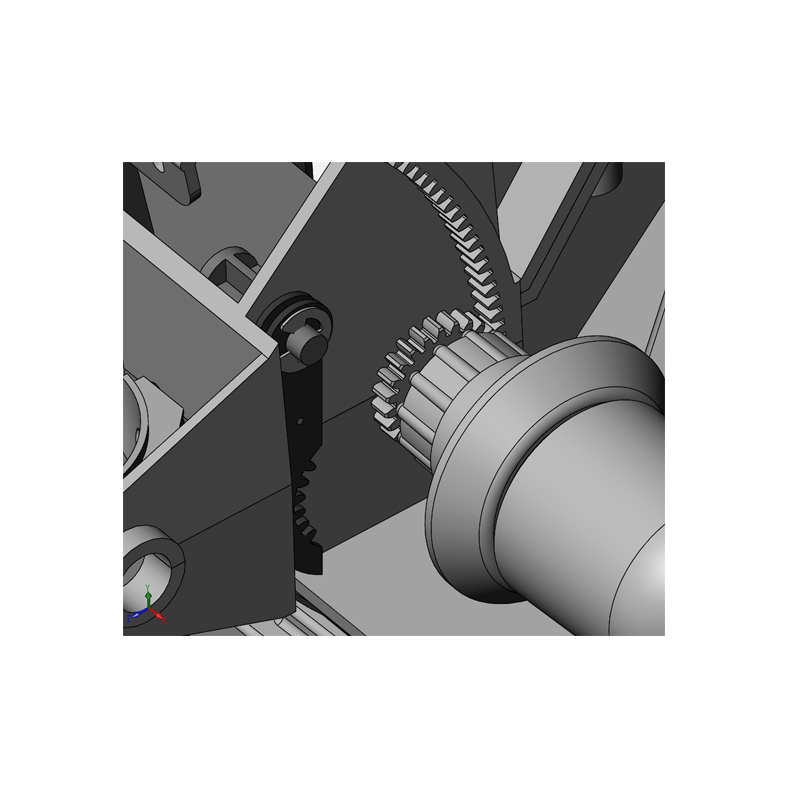

BH initiated the project with a rapid Discovery phase to better understand the limitations and issues with current systems, including leading competitors. Synthesis from the usability study suggested multiple innovations such as integrating a corded remote controller so that the device could be easily operated with reasonable separation between subject and operator to enhance ease-of-use for both test subject and operator. The optical pathway was folded into a "Z" layout to shorten overall device length to enhance portability and reduce weight. The subject interface was carefully designed to match normal postures from a standing child to a seated adult by developing a non-parallel dual arm mechanism. BH also invented an in-line LCD pointing filter that electro-optically highlighted the test image, controlled from the remote while also preserving optical integrity (the previous design required opening a light-bleeding hatch to observe a mechanical pointer!). BH managed the mold fabrication in China and preparation of pilot plastic kits until the molds were qualified and production ramped up.

Titmus ultimately secured multiple patents on the device that protected the i-500 and subsequent device designs from global competitors.

Duration- 12 months